R2 out on the town.

Wednesday, December 4, 2013

Tuesday, October 22, 2013

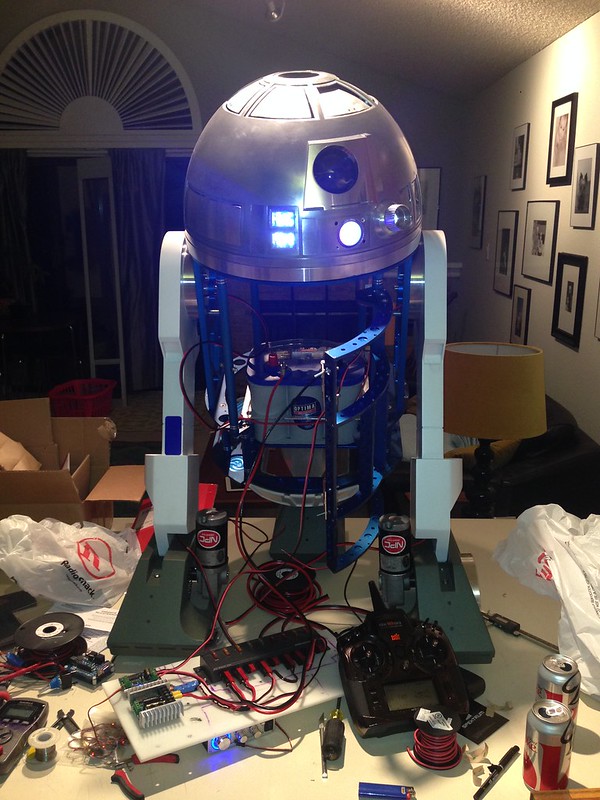

Getting Ready for Halloween!

Got some fancy booster covers in from Mcwhlr. These things are nice.. SUPER light. Only thing to do was some serious sanding and polishing. Took quite awhile but got it pretty shiny.

Front all finished using temp resin utility arms.

all masked off and ready to paint.

And all nice and blue!

Also got a dome bump controler kit :))) Cut the hole and checked the fit.

Monday, October 14, 2013

Paint Time

Well even though I loved how the dykem turned out on the ankle cylinders my tests confirmed what everyone had been saying... Dykem fades... even with the nice 2 part uv clear coat.

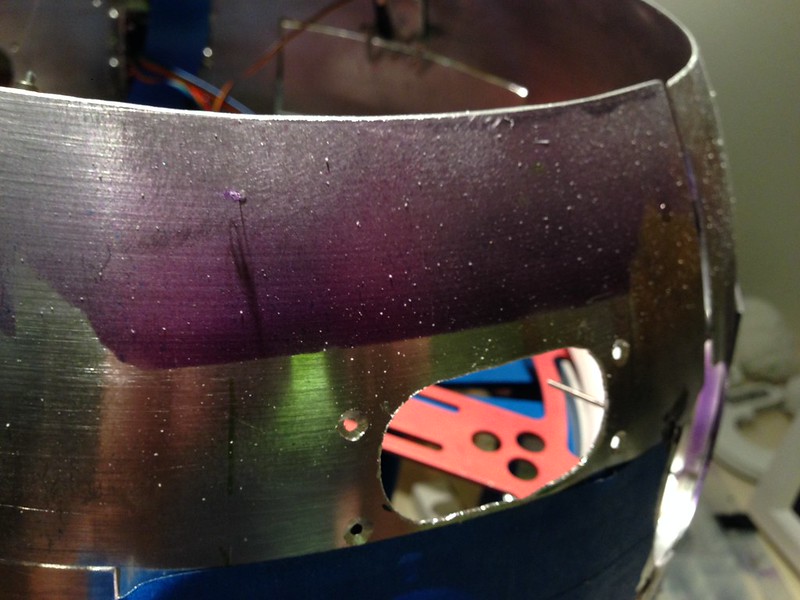

Ive seen others curiousmarc, strongbow, and now edwardo try the duplicolor metalcast anodized purple instead of the dykem. My tests showed also that its very close. Here was the process...

First i wet sanded all my parts to 2000 grit.. Then i used micromesh and wet sanded to 12000.. Followed by mothers aluminum polish.

'

Ive seen others curiousmarc, strongbow, and now edwardo try the duplicolor metalcast anodized purple instead of the dykem. My tests showed also that its very close. Here was the process...

First i wet sanded all my parts to 2000 grit.. Then i used micromesh and wet sanded to 12000.. Followed by mothers aluminum polish.

'

Bare

Metal cast purple anodized

And the blue anodized.

And hers after using Spraymax 2k two part UV clear coat. THIS STUFF IS GREAT.

Here is an example of putting it on too thick. I think i put it on a little too thick on most of my panels. I did this test on my two radar eyes. One on the left i put on too thick. The one on the right is just right.

Some feet work

Lots of loose parts.

Cut some strips from some 1/8" by 1" alum. I marked the holes up against the feet then drilled a pilot hole followed by step drilling it to fit the khf's

Assembled the painted feed and installed the hose fittings as well as a tube to protect the npc wires.

Cut some strips from some 1/8" by 1" alum. I marked the holes up against the feet then drilled a pilot hole followed by step drilling it to fit the khf's

Assembled the painted feed and installed the hose fittings as well as a tube to protect the npc wires.

Center Leg all finished minus strips.

Monday, September 30, 2013

First Blue Parts (Dykem)

Well i really love how dykem looks. Im pretty much following the great examples of those before me such as curiousmarc.

However im using spray max 2k, 2 part clear coat. These are special paints that when when activated mix internally and the cans only last 48 hours. My first try with it and it rules. SUPER clear nice thick clear coat!

Im using an iwata single action airbrush to apply the dykem. Then using the duplicolor metalcast anodized blue to knock down the purple some in the dykem followed by the uv clear coat.

Here's my first few pieces. I need to polish the rest of the parts more before i spay them.

However im using spray max 2k, 2 part clear coat. These are special paints that when when activated mix internally and the cans only last 48 hours. My first try with it and it rules. SUPER clear nice thick clear coat!

Im using an iwata single action airbrush to apply the dykem. Then using the duplicolor metalcast anodized blue to knock down the purple some in the dykem followed by the uv clear coat.

Here's my first few pieces. I need to polish the rest of the parts more before i spay them.

Couple odds and ends

Final painting on the feet parts started

Some paint on the shoes

a little more welding on the battery box's (still learning)

First Steps

Well R2 took his first steps!

They were a little sketchy which is why i decided to move the center caster in the last post.

They were a little sketchy which is why i decided to move the center caster in the last post.

Friday, September 27, 2013

Decided to move my caster forward in the center foot. I just took the metal plate i got with my jag bracket and cut it to fit. Then just used the same plate i already had and bolted it right to it. I counter sunk the screws so the caster would sit flush. Then i welded some nuts on the back so i could secure the caster easily. The whole thing bolts together in a couple stages from the bottom so no tricky screws to reach etc.

The caster is moved fwd as far as possible.

Heres the pics

Heres the pics

caster position when reversing...

caster position when moving forward

Monday, September 23, 2013

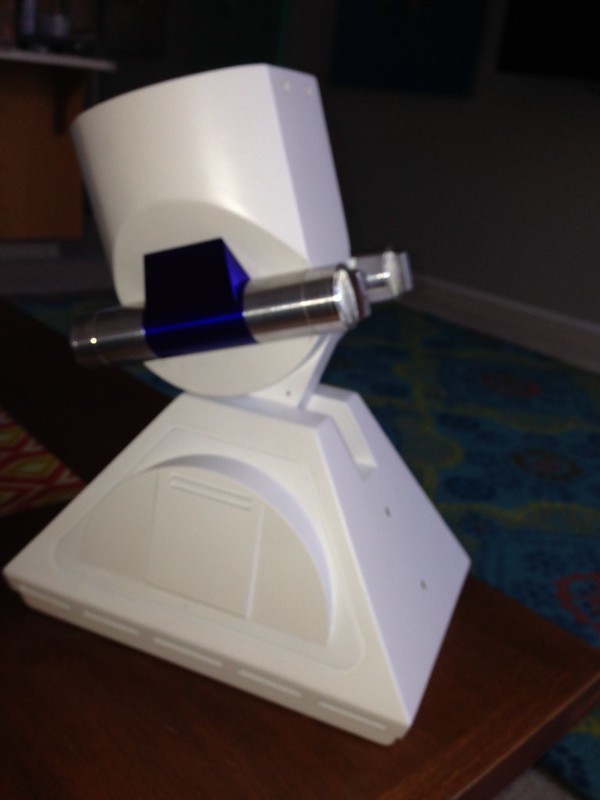

Electronics Panel

Next i needed somethin to mount the electronics too. I had a big chunk of delrin and cut it to size. I decided to make a folding electronics panel and mount it to the door. This way it it will fold out and provide easy access to both sides of the panel.

Heres a vid of how it folds out.

Testing the electronics.

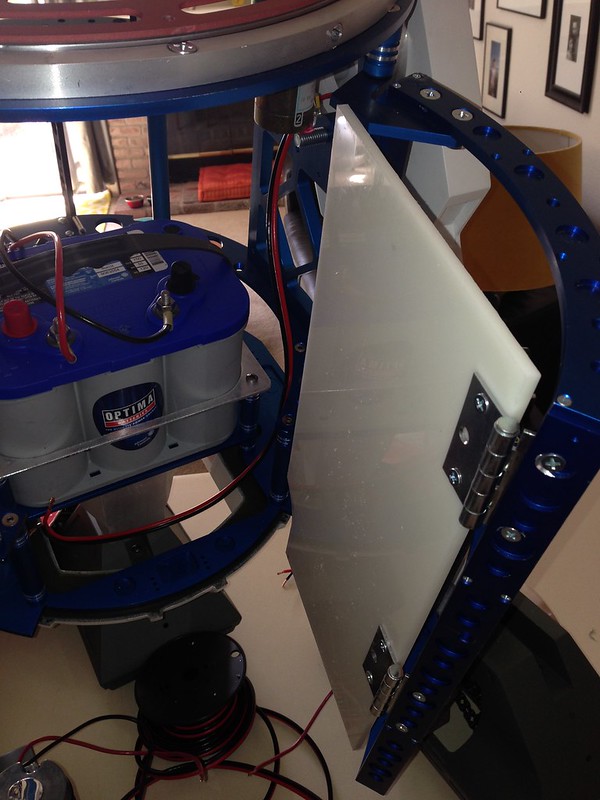

Battery Mounting

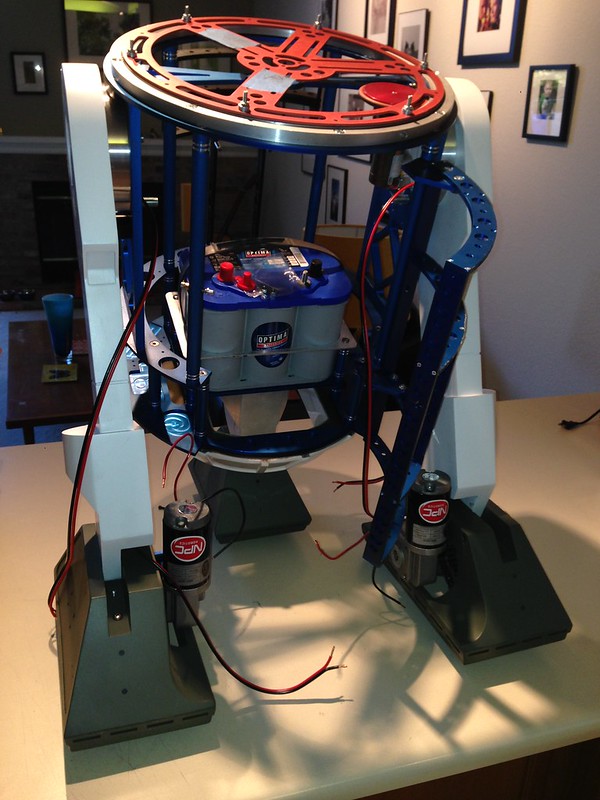

We'll since i got legs on this little guy i figure he needs some power. I planned to go 2-3-2 at some point and ordered a frame upgrade to do so... However I wanna get him done before holloween. So i decided to go with an optima blue top batter.... HEAVY but as many say i wont have to worry about running out of juice.

The first prob is i didnt have a way to mount it. My frame had the 3 slots for the smaller sla batteries. No worries pulled out the jig saw and cut out a new plate to fit the optima. I also sanded off the lip on the bottom of the battery.

The first prob is i didnt have a way to mount it. My frame had the 3 slots for the smaller sla batteries. No worries pulled out the jig saw and cut out a new plate to fit the optima. I also sanded off the lip on the bottom of the battery.

Here is is with the battery inserted.

Thursday, September 19, 2013

Ankle Locks

Since Im using a single caster on the middle foot i need to lock it from pivoting. I just took some 1/4" aluminum and cut out some wedges to lock it in place.

To make the template i held up a piece of card stock level with the top of the foot and took a pencil and rubbed along the edge of the ankle radius. This transferred the curve perfectly. Then cut and traced that onto the aluminum and cut with a band saw. Next i smoothed and adjusted with belt sander.

Then i just tapped a hole in the ankle and attached. Seems to work quite nicely. No play either way.

Ill do a little more trimming to make it pretty.

To make the template i held up a piece of card stock level with the top of the foot and took a pencil and rubbed along the edge of the ankle radius. This transferred the curve perfectly. Then cut and traced that onto the aluminum and cut with a band saw. Next i smoothed and adjusted with belt sander.

Then i just tapped a hole in the ankle and attached. Seems to work quite nicely. No play either way.

Ill do a little more trimming to make it pretty.

HE STANDS!!!!

Test fitting some leg parts.

Had to cut, drill, and tap a center ankle addapter.

He Stands for the first time!!!

Wednesday, September 11, 2013

Monday, September 9, 2013

Aluminum Battery Box

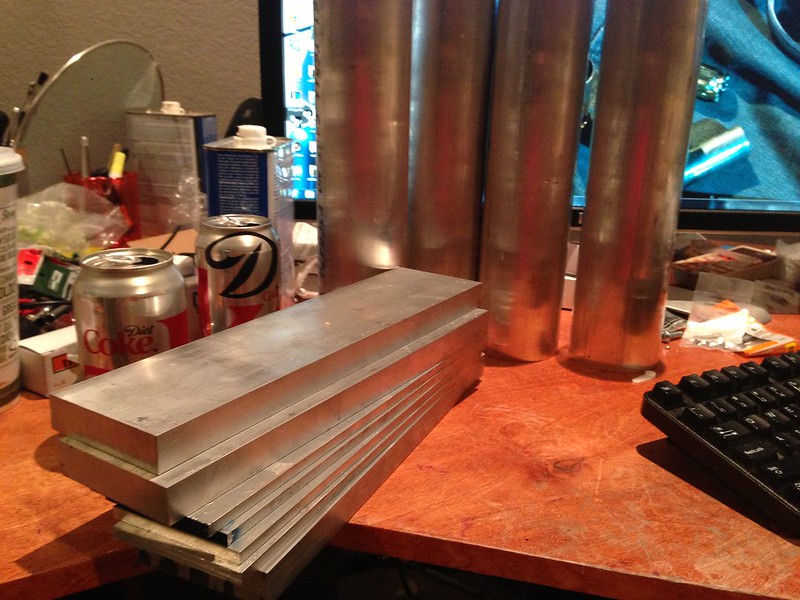

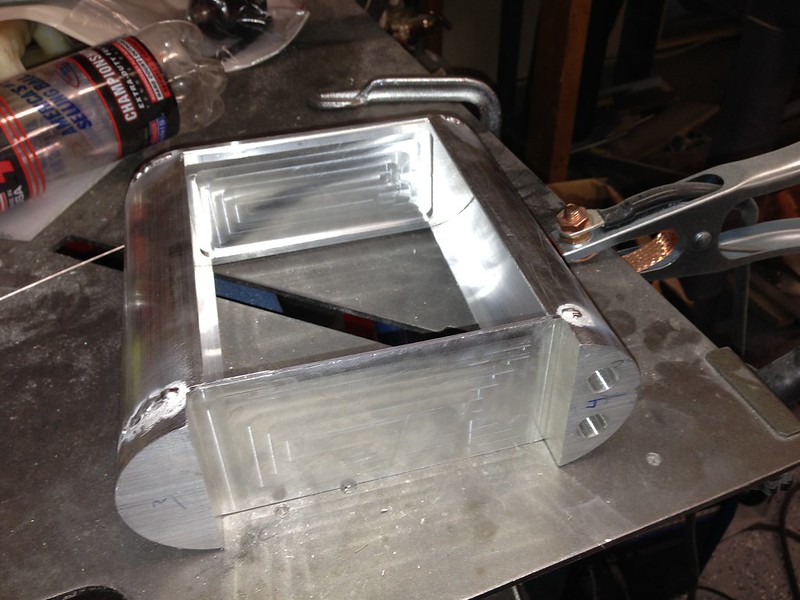

So i decided to make some aluminum battery box's... Other than the battery harnesses this is one of the last parts i need for r2. These are 8.25 Inches tall and should fit my NPC motors.

I first designed it out in cad with alibre. I ordered up my aluminum.

I first designed it out in cad with alibre. I ordered up my aluminum.

Battery box's see em? I do :)

Stock clamped and ready to cut.

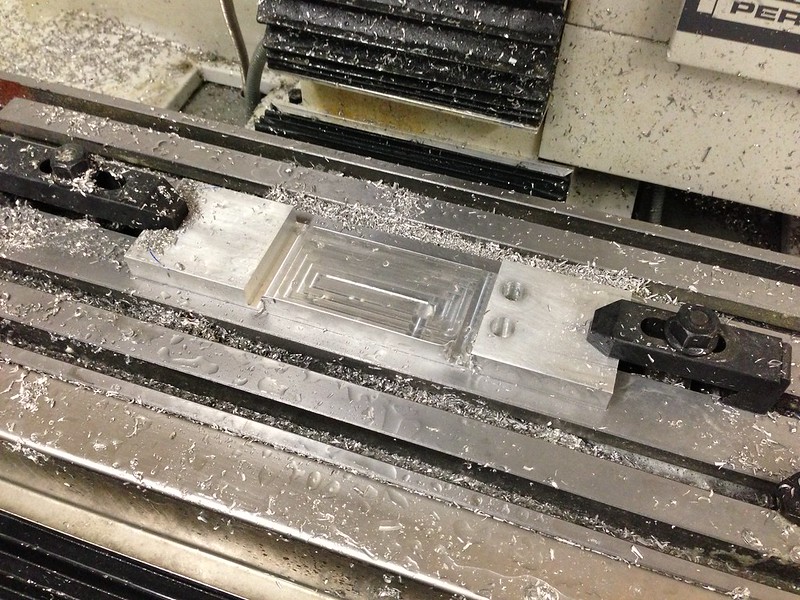

Makin chips.

Front done.

Parting the back.

Heres the back end cap. Milled out a pocket for lightness. If you look close you can see the step around the ends. This makes it very easy to align the skins parts.

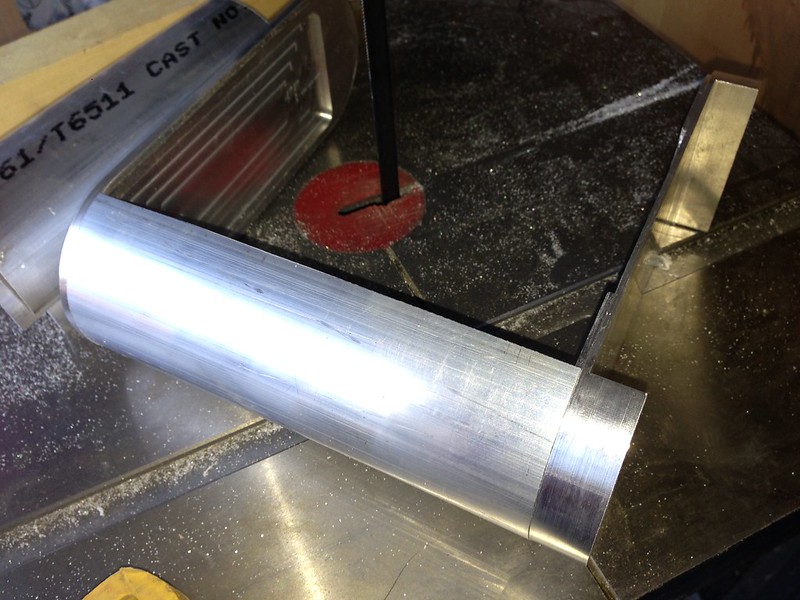

I cut the 3" aluminum tube in half for the top and bottom. Look at that perfect fit!

Now the ugly :) Im still learning to Tig Weld. Ill grind off these ugly welds once im all done and it should look nice and smooth.

I had to get some more argon gas so the rest of the welds will have to wait.

Sunday, September 8, 2013

Sanding Dome Panels

This is pretty straight forward post. I finally got around to sanding all of the dome panels all the way to 2000 grit. I followed the same method as with my dome. Started with 320 on an orbital sander, next 400, 600, 1000, 1200, 1500, and finally 2000.

After 600 Grit

After 2000 Grit

Subscribe to:

Posts (Atom)